Mapa

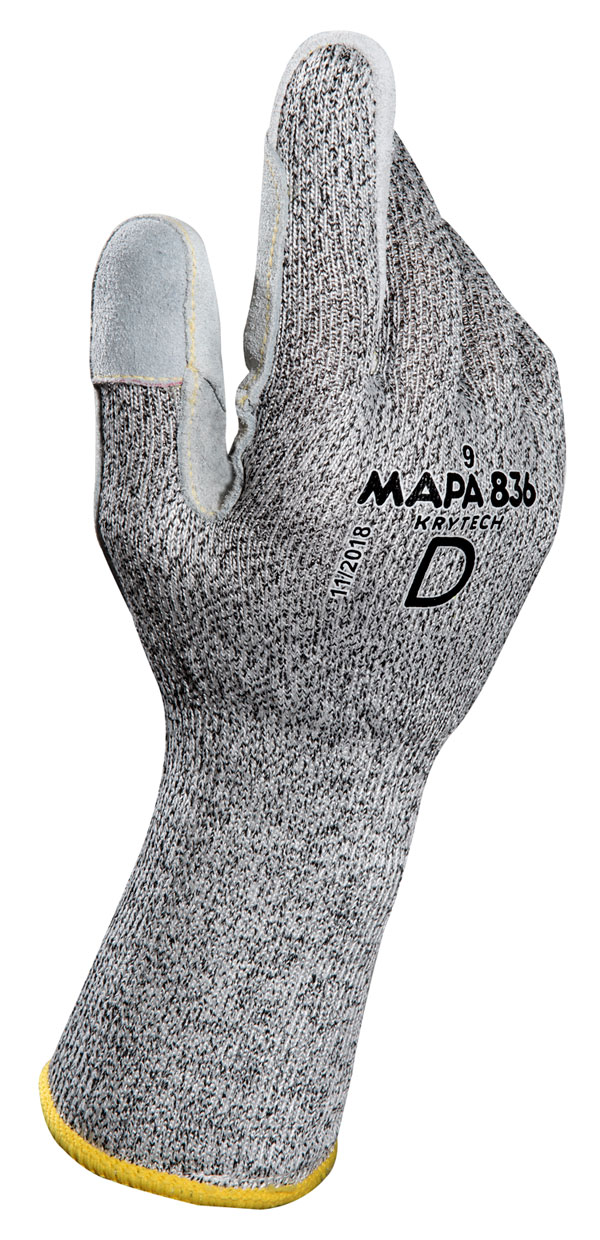

• Excellent cut protection and resistance to wear with optimal dexterity and comfort

• Protection of the forearm thanks to its longer cuff

• Good resistance to wear and good puncture resistance (barbs) due to leather palm

• Reinforced crotch between thumb and forefinger

• Seamless textile support from HDPE fibres

• EN 388:2016 Protective gloves against mechanical risks 4X43D

• EN 407 Protective gloves against thermal risks X1XXXX

Key applications with the Automotive and mechanical industry include:

• Metal working

• Handling untrimmed parts or sheet metal

• Handling sheet metal

• Handling parts post-press

• Cutting strips (plasma etc.)

• Natural rubber coated high protection for handling heavy or sharp objects in wet environments

• High protection level D against cuts

• Thermal insulation of the hand

• Good grip for picking up heavy parts safely, due to embossed texture

• Good puncture-resistance

• EN 388:2016 Protective gloves against mechanical risks 3X43D

• EN 407 Protective gloves against thermal risks X2XXXX

Key applications:

Ceramic and plastics industry:

• Post-injection handling of hot plastic parts

• Handling of composite materials after heat processing

Construction Industry (Carpenters/Joiners)

Cutting wood

• Installing steel structures

• Assembly

• Screwing

• Studwork

• Local Authorities (Waste Collection and Processing) -Processing waste at a sorting centre

• Glass industry -Handling glass sheets

• Nitrile coated, combined long lasting cut, thermal and chemical protection

• Textile support Mapa Technology

• Total hand protection

• Level D protection against cuts

• Entirely liquid proof, withstanding mechanical aggression

• Proven long-lasting performance

• Good grip for picking up wet and slippery objects safely

• 320mm length

• EN 388:2016 Protective gloves against mechanical risks 4X43D

• EN ISO 374-1:2016 Type B Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for chemical risks, JKOPT

• EN ISO 374-5:2016 Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for micro-organisms risks

• EN 407 Protective gloves against thermal risks X1XXXX

Key applications include:

Automotive/mechanical industry

• Sheet metal

• Metal rolling, stamping and assembly

• Cutting aluminium strips

Other industries -Collection and sorting of industrial and household waste

• Natural rubber coated, textile supported for maximum comfort for long-term work in aggressive environments

• Freedom of movement, due to the anatomical shape and excellent comfort from the seamless textile support

• Good tear resistance

• Good resistance to many diluted acids and bases

• EN 388:2016 Protective gloves against mechanical risks 2131X

• EN ISO 374-1:2016 Type B Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for chemical risks, KPT

• EN 407 Protective gloves against thermal risks X1XXXX

Key applications include:

• Construction Industry (Masons / Plasterers) - Preparing and pouring mortar and cement

• Aeronautics industry - Work with composite materials (resins)

• Local Authorities (Cleaning) - Handling household detergents

Liquidproof glove, embedding antimicrobial Pylote's technology, that limits cross contamination by viruses & bacteria.

• 405 Activated provides a protective shield against viruses and common aggressive chemicals

• Surface protection: destruction of 99% viruses (ISO 21702:2019) & 99.99% bacteria (JIS Z 2801 standard)

• Antimicrobial action lasts for the expected lifetime of the glove

• Good grip due to the non-slip embossing

• Reduced thickness offering Tactile Sensitivity (0.7mm)

• Cotton flocking provides added comfort and perspiration absorption

• Produced using polychloroprene and natural latex

• 330mm length

• EN 388:2016 Protective gloves against mechanical risks 2110X

• EN ISO 374-1:2016 Type B Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for chemical risks, KMT

• EN ISO 374-5:2016 Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for micro-organisms risks

• EN 421 Protective gloves against ionizing radiation and radioactive contamination

• PVC coated fabric supported. Comfort, flexibility, mechanical protection with grip and chemical protection

• Exceptional comfort and good resistance to cold, due to the seamless cotton-knit

• Good resistance to oils, greases and hydrocarbons

• Suitable for food contact

• 1.35mm thickness, 300mm length

• Exterior pebbled finish and scalloped cuff

• EN 388:2016 Protective gloves against mechanical risks 4121 3141X

• EN ISO 374-1:2016 Type A Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for chemical risks, KLMNPT

• EN ISO 374-5:2016 Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for micro-organisms risks

Key applications include:

• Pharmaceutical industry: maintenance and cleaning

• Maintenance in wet environments

• Mechanical industry: Maintenance in wet environments (water, oil, greases, hydrocarbons)

• Neoprene fabric supported gauntlet, effective thermal insulation and chemical protection

• Multi-purpose chemical resistance (acids, aliphatic solvents) increased by the thickness of the material

• Excellent thermal insulation, due to double-knit cotton

• Good grip of wet or slippery objects, due to embossed texture

• Knitted thermal protection interior

• Pebbled exterior finish

• EN 388:2016 Protective gloves against mechanical risks 2212X

• EN ISO 374-1:2016 Type A Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for chemical risks, ACLMNS

• EN 407 Protective gloves against thermal risks X2XXXX

• EN 511 Protective gloves against cold 111

Key applications include:

• Petrochemical industry - Sampling of hot petrochemical products

• Rubber industry -Polymer extrusion

• Mechanical industry- Chemical treatment of metals & oil quenching of steel

• Steam cleaning

• Road works in cold conditions

• Manufacture of insulating electric wires

• Boiler room work

• Manufacture of adhesives

• Handling of moulds in the ceramic industry

• Handling of hot piping

• Highly durable double nitrile coated cut protective glove

• Special Grip & Proof finish which ensures liquidproofness and grip in oily situations

• Optimal cut resistance: level D (ANSI Cut 4)

• Excellent abrasion resistance increases glove lifetime

• Visible indicator in blue textile to easily identify the cut-performance level in the workplace

• Washable for 5 cleaning cycles

• Available in vending machine packaging

• EN 388:2016 Protective gloves against mechanical risks 4X43D

Key applications include:

Automotive/mechanical industry

• Metal working

• Assembly of thin metal sheets

• Metal rolling, stamping and assembly

• Handling metal parts

• Finishing sharp parts

• Glass industry - Handling glass sheets

• Mechanical industry- Cutting and stamping metal

• Natural rubber coated, textile supported. Comfort and safety when gripping heavy, rough or slippery objects in highly aggressive environments

• Suitable for long-term wear, due to the comfort of a textile support

• Good thermal insulation

• Optimised service life: high resistance to abrasion

• 1.35mm thickness, 320mm length

• Reinforced grip and scalloped cuff

• EN 388:2016 Protective gloves against mechanical risks 3141X

• EN ISO 374-1:2016 Type B Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for chemical risks, KPT

• EN 407 Protective gloves against thermal risks X1XXXX

Key applications include:

• Fishing

• Fish-handling

• Oyster farming

• Work with frozen products

• Neoprene and natural rubber textile supported chemical gauntlet

• Suitable for long-term wear; added comfort of textile support

• Longer service life for heavy-duty work: good mechanical resistance

• Forearm protection

• 1.45mm thickness, 380 mm length

• Smooth exterior and scalloped cuff

• EN 388:2016 Protective gloves against mechanical risks 2121X

• EN ISO 374-1:2016 Type A Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for chemical risks, ACLMNS

• EN ISO 374-5:2016 Protective gloves against dangerous chemicals and micro-organisms. Terminology and performance requirements for micro-organisms risks

• EN 407 Protective gloves against thermal risks X1XXXX

Key applications include:

• Automotive/mechanical industry -Battery, pump, and compressor manufacturing

• Chemical industry - Chemical treatment of metals & handling and transporting chemicals

• Other industries - Industrial cleaning, maintenance & timber treatment

• Comfort, suppleness and high dexterity without any compromise on breathability and durability

• Comfort: high suppleness and flexibility, dexterity at fingertips, proven breathability

• Resistance: Extended use guaranteed by our exclusive process ResiComfort, coating provides resistance to friction

• Washable: 1 time at 40°C

• STANDARD 100 by OEKO-TEX® / Dermatological certification / Silicon Free / DMF free

• Nitrile foam sandy palm

• Interior seamless textile support finish

• Reinforced grip exterior finish

• EN 388:2016 Protective gloves against mechanical risks 4121A

• EN 407 Protective gloves against thermal risks X1XXXX

Key applications include:

Automotive/mechanical industry

• Assembly of small parts

• Automotive assembly

• Fitting small screws and fasteners

• Precision assembly

• Precision mechanical work

• Mechanical maintenance

Other industries

• Packaging

• Warehousing and receipt of goods